Galax to Use Machine-Intelligent Technology to Address Regulatory Violations By Finding Rain-Dependent Infiltration That Causes Sanitary Sewer Overflows

Sacramento, CA, USA, May 2, 2017 – Electro Scan Inc. is delighted to announce the selection of the City of Galax, Virginia for a complimentary Electro Scan Pilot to find and measure sources of infiltration in their sanitary sewer system. The pilot giveaway was held in conjunction with Electro Scan’s 2017 Trenchless Technology webinar, and was created to bring much-needed Electro Scan services to small agencies that have a desire to address issues with their system, but may not have the necessary budget and resources.

The City of Galax was selected because of their unique project attributes, pipe locations and criticality, and financial need. The 2-day project is expected to start in the fall of 2017, and will include the assessment of 5,000 linear feet of vitrified clay pipe (VCP) and polyvinyl chloride pipe (PVC). A full report will be provided to the City, quantifying potential infiltration in gallons per minute (GPM) to help them prioritize pipes for rehabilitation.

From 2003 to 2013, the City of Galax was under a Consent Decree from the United States Environmental Protection Agency (USEPA) and the Virginia Department of Environmental Quality (VADEQ) where they were required to develop a Capacity, Management, Operation, and Maintenance (CMOM) Program.

“Initial CMOM inspection projects were able to identify and eliminate the larger, more obvious infiltration issues, but locating additional infiltration problem areas has since become very difficult. We are happy to have been selected for the Electro Scan Pilot because of the technology’s ability to find and measure potential sources of infiltration, even if there is not an active leak in that moment,” stated Edwin Ward, P.E., City Engineer, City of Galax.

One of the only manuals referenced in the EPA’s CMOM Program is the Volume One, Operation and Maintenance of Wastewater Collection Systems manual, authored by the late Ken Kerri, Ph.D., P.E. In the new seventh edition (published December 2015) of the manual, a chapter on Electro Scanning Inspection was included to overcome the limitations of visual inspection. The chapter recommends the use of Electro Scanning Inspection, over CCTV, to evaluate sewer pipes before and after rehabilitation.

“CCTV operators are rarely successful when they are forced to wait for a wet weather event to put a camera in a pipe to visually look for infiltration in an overwhelmed collection system. Electro Scan creates a wet-weather event from within the pipe to predict infiltration before it happens, and before a disastrous SSO occurs,” states Chuck Hansen, Chairman, Electro Scan Inc.

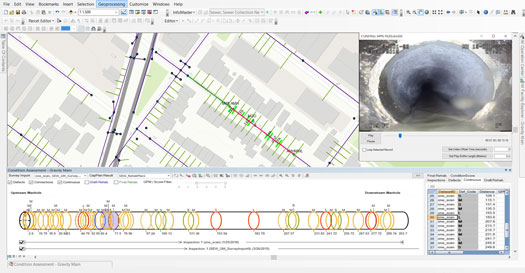

Electro Scan Inspection uses patented technology to measure the variation of electrical current that flows through cracks, bad joints, defective service connections, and other defects in non-conductive pipe materials.

Using its Critical Sewers® cloud application, defects are automatically located and measured in GPM, with unambiguous reports available in minutes from any device with an internet connection.

All Electro Scanning Inspection projects are conducted in accordance with ASTM F2550-13, Standard Practice for Locating Leaks in Sewer Pipes by Measuring the Variation of Electric Current Flow Through the Pipe Wall and the Seventh Edition, Volume One, of the Operation and Maintenance of Wastewater Collection Systems manual.

About Electro Scan Inc.

Electro Scan Inc. develops proprietary pipe condition assessment instrumentation and cloud applications that automatically locate, measure, and report defects in sewer, water, and natural gas pipelines, typically not found by legacy inspection methods.

Contact

Electro Scan Inc., Carissa Boudwin, +1 916-779-0660, info@electroscan.com