Tennessee Sewer District Adopts Machine-Intelligent Focused Electrode Leak Location (FELL) to Automatically Locate and Quantify Pipe Defects

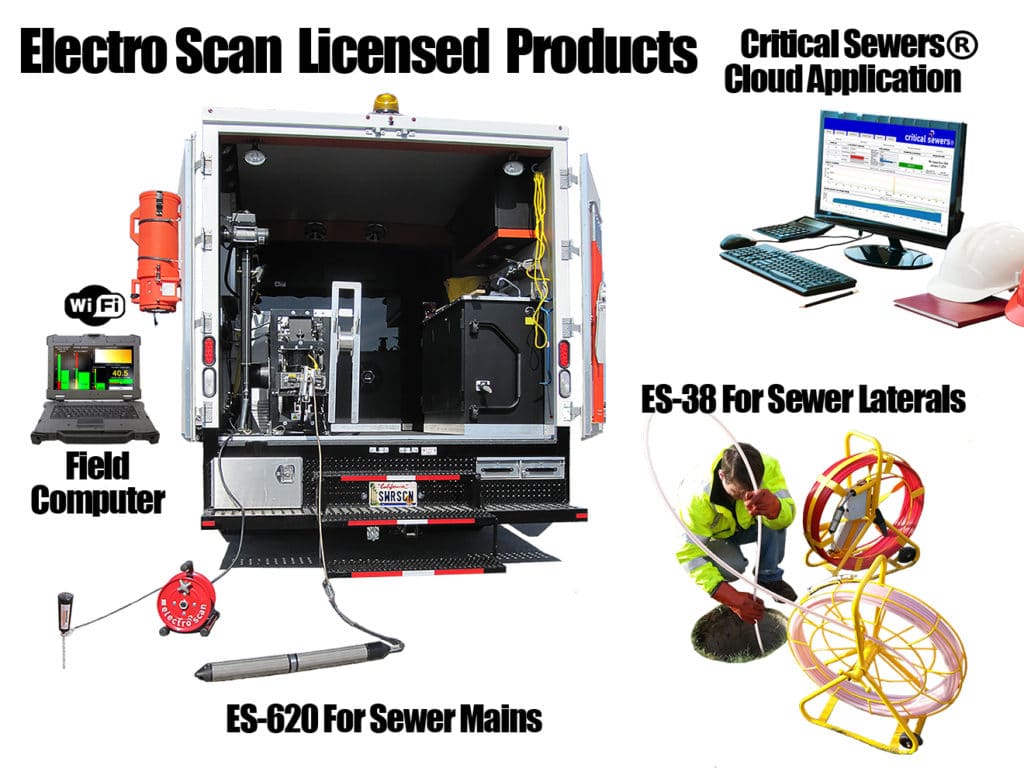

January 28, 2020 /EINPresswire.com/ — Electro Scan Inc. announced today that West Warren-Viola Utility District (District), Morrison, Tennessee, has added the Company’s machine-intelligent Focused Electrode Leak Location (FELL) technology to the District’s current field inspection fleet. The Company’s patented ES-620 for Sewer Mains and ES-38 for Sewer Laterals will be purchased and operated by the District.

The District operates and maintains over 50,000 feet, or 10 miles, of sewer collection mains ranging from 8- to 12-inches in diameter. The District treats nearly 1 million gallons of wastewater per day, which increases dramatically during wet weather events due to leaking pipes in its existing system.

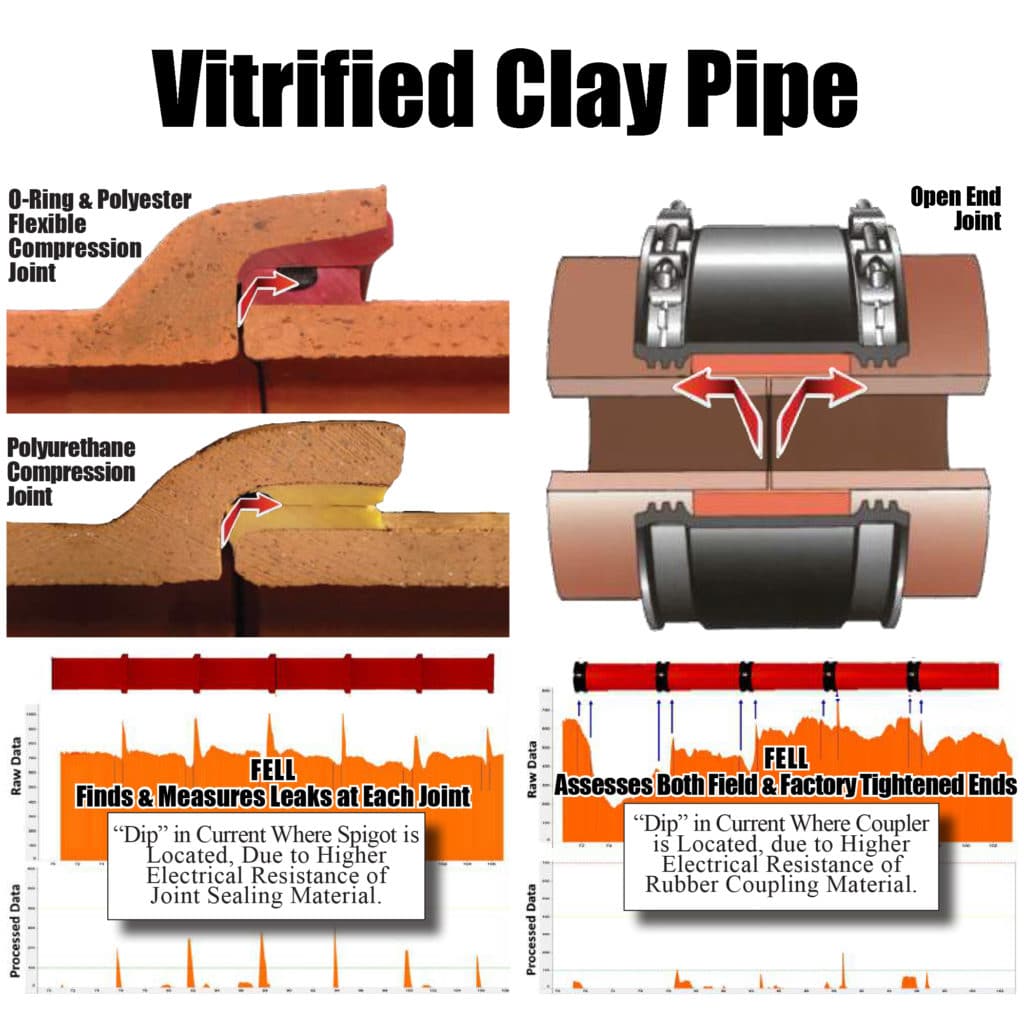

FELL technology automatically locates and quantifies defects in minutes, without the need for third party data processing or evaluation and does not require manual coding by field operators. Electro Scan technology will be used to locate leaks contributing to unwanted infiltration and to prioritize pipes for rehabilitation within the District’s sewer system.

“We want to get our moratorium lifted on adding new sewer connections and this will go a long way to pinpoint our largest sources of infiltration,” stated Tim Pelham, General Manager, WWVUD.

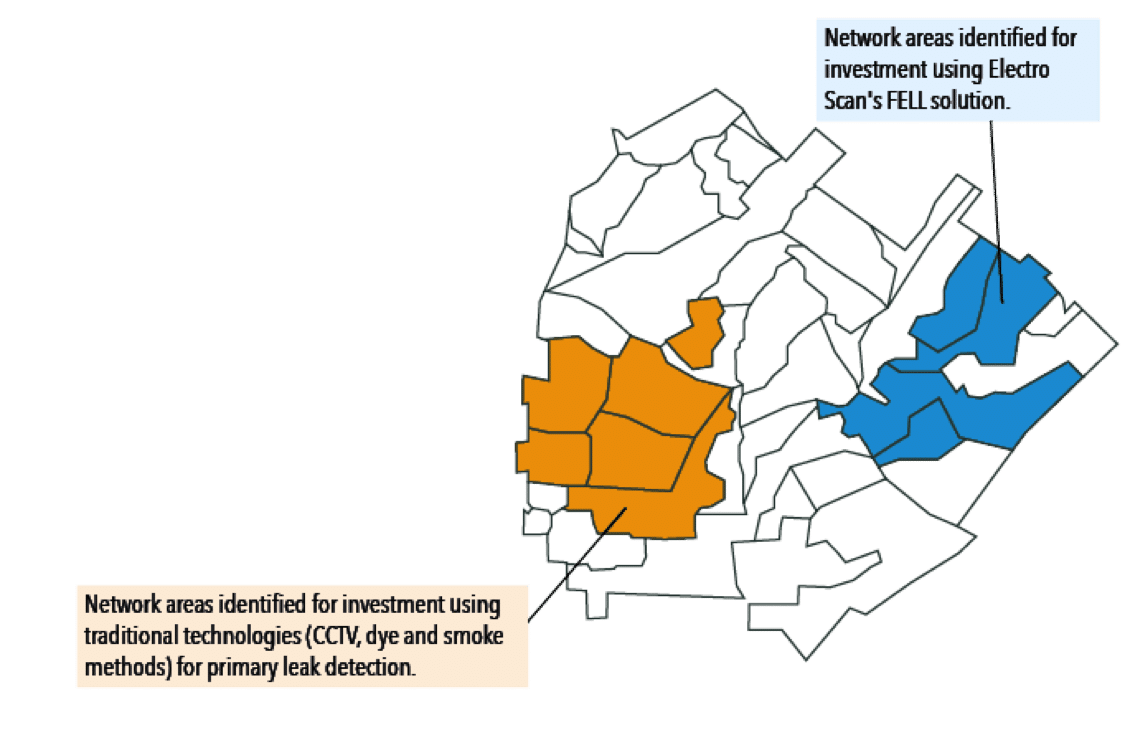

According to the University of Michigan Center for Sustainable Systems, there are nearly 15,000 Publicly Owned Treatment Works (POTWs) in the United States that treat wastewater from 1.2 million miles of collection sewers. These systems serve almost 250 million people and adopting FELL technology overcomes many of the drawbacks from legacy assessment techniques to accurately find and measure leaking pipes. As a result, wastewater agencies can target their limited capital to where it is needed the most. ‘Doing more with less’ while serving the needs of rate payers everywhere.

“Whether you are responsible for 10 miles of pipe or 10,000 miles of pipe, accurate condition assessments & unbiased testing of repairs, rehabilitation, and replacement projects need to be performed one-pipe at a time,” stated Chuck Hansen, CEO and Founder, Electro Scan Inc.

Consulting engineers from James C. Hailey & Company (Brentwood, TN) assisted the District in its evaluation and purchase of the equipment and had invited the Electro Scan field team to demonstrate its technology for the District in its own collection network.

“Agencies like West Warren-Viola Utility District can’t afford to miss-prioritize repairs & rehabilitation,” stated Nathaniel Green, P.E., Principal, James C. Hailey &. Company. “And, even the best cameras that rely on visual inspection can’t correctly assess most pipes.”

“CCTV, at best, can be hit-or-miss at finding infiltration,” stated Green. “The District had received USDA funding to help eliminate major sources of infiltration, and we wanted Electro Scan to show us what we couldn’t find using CCTV cameras.”

Rehabilitation selections will be based on FELL results with construction funding provided from a U.S. Department of Agriculture (USDA) Loan / Grant combination.

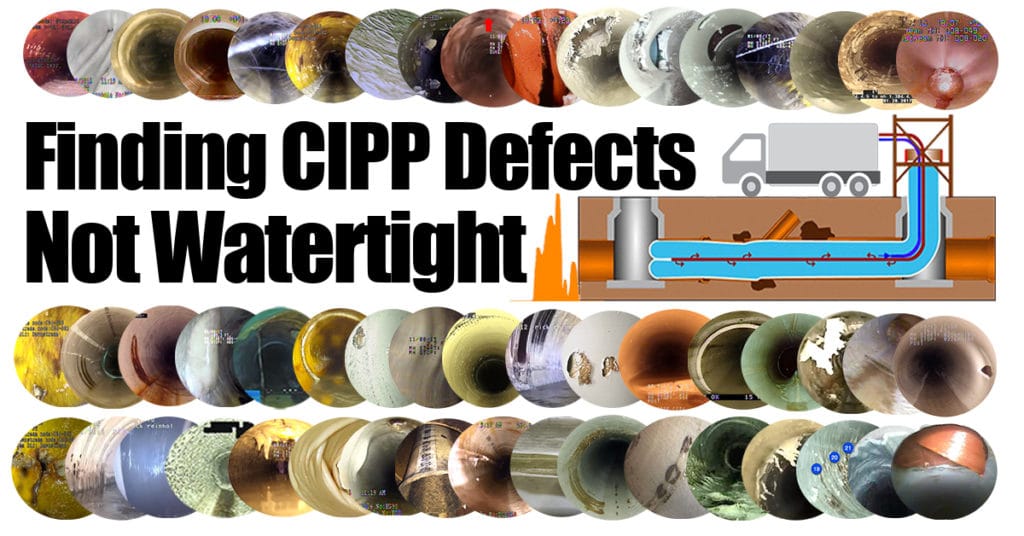

FELL inspection will also be used to test and certify rehabilitation work to determine if Contractors have delivered watertight pipes that conform to contract requirements.

“During the field demonstration, the Electro Scan Services team evaluated two (2) pipe materials, and not only confirmed what we saw using a CCTV camera but found pinhole leaks in PVC that couldn’t be seen. In the RCP, Electro Scan measured leaks at known bad joints, but also located corrosion and bad joints that looked good on CCTV,” stated Mark Parker, Wastewater Superintendent, WWVUD.

Four (4) pipes were selected as a demonstration to compare FELL results with manually coded data from legacy CCTV inspection, including three (3) 8-inch reinforced concrete (RC) pipes and one (1) 8-inch polyvinyl chloride (PVC) pipe. The reinforced concrete pipes proved to have moderate corrosion with large defects each joint that were not previously seen using CCTV inspection.

The demonstration was organized by Tim Kazmier, Kazmier & Associates (Lenior, TN), the exclusive representative of Electro Scan products & services in Alabama, Georgia, and Tennessee.

“CCTV and FELL results were compared, showing that CCTV was lacking in locating and measuring potential infiltration.” stated Parker. “We realized this technology could take our condition assessment programs to the next level with its ability to estimate leaks in gallons per minute.”

While CCTV pipe inspection had been used by the District for decades, as with many other agencies, and will continue to be used to help document obstructions, accumulated fats, oils, grease, and roots, FELL technology is needed to correctly locate and measure pipe leaks to pinpoint needed repairs, and certify rehabilitation and new pipe installations as watertight.

A key advantage of FELL technology is its ability to automatically identify and quantify leaks at joints, customer lateral connections, and cracks, without subjective or third-party analysis or specialized training.

The technology can also identify pinhole leaks from trenchless rehabilitation projects, including Cured-In-Place Pipe (CIPP), as well as defects at customer lateral locations that may not have been present before lining or lateral reinstatement.

The ES-620 equipment will be seamlessly integrated into the District’s existing Cues CCTV truck, allowing the operators to easily switch between FELL and CCTV inspection methods within minutes.

Electro Scan’s FELL technology has been evaluated in benchmark studies by the U.S. Environmental Protection Agency (USEPA), the American Society of Testing and Materials (ASTM), and the Water Environment & Reuse Foundation (WERF). Likewise, the German Institute of Underground Infrastructure (IKT), the UK-based Water Research Centre (WRc), and the Japanese Sewer Collection System Maintenance Association (JASCOMA) have all studied and endorsed FELL technology for pipeline condition inspection.

Uncontrolled inflow and infiltration (I/I) in gravity sewers results in significant and unnecessary costs to the District and its rate payers.

By precisely identifying and quantifying I/I within the District’s pipelines, infrastructure integrity is improved maximizing system capacity and avoiding costly and unnecessary capital expenditures.

Electro Scan is the only supplier, worldwide, that produces reporting in accordance with ASTM F2550, ‘Standard Practice for Locating Leaks in Sewer Pipes by Measuring the Variation of Electric Current Flow Through the Pipe Wall.’

“West Warren-Viola Utility District may be a small agency, but the importance of reducing flows due to unwanted infiltration and making cost-effective rehabilitation decisions is the same for every utility,” stated Mike App, Vice President, Electro Scan Inc.

ABOUT WEST WARREN-VIOLA UTILITY DISTRICT

The District provides sewer services to the Town of Morrison, Mountain View Industrial Park, commercial developments along the Highway 55 corridor, and a large residential neighborhood near the McMinnville Country Club. Created pursuant to Order of the County Executive of Warren County, Tennessee, entered on June 9, 1982, the District resulted from the merger of the West Warren Utility District of Warren County, Tennessee, and the Viola Utility District of Warren County. Following an Order Granting Petition in 2008, the District was granted approval for West-Warren Viola Utility District to expand its boundaries into Coffee County, recreating the District as a two (2) county utility district.

ABOUT ELECTRO SCAN INC.

Electro Scan Inc., a leading supplier of machine-intelligent pipeline assessment products and services for the water & wastewater pipeline market, was named to Government Technology’s esteemed 2020 GovTech 100 list for the second year in a row. Electro Scan Inc. develops proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing and reporting applications that automatically locate, measure, and report defects in sewer, water, and natural gas pipelines, typically not found by legacy inspection methods.