Rapid Adoption of Electro Scan Inspection By Northern California Sewer Agencies Follows Release of New Wastewater Guidelines

New Projects Address Violations of the Clean Water Act and Mandatory Reductions in Sanitary Sewer Overflows

SACRAMENTO, Calif. – June 13, 2016 – Electro Scan Inc. has begun numerous projects in Northern California to independently assess the condition of sanitary sewers, before and after rehabilitation programs.

“We are delighted to begin so many projects near our headquarters,” stated Chuck Hansen, Chairman of Electro Scan, “and to show how sewer agencies can reduce their reliance on outdated methods of inspection that may inaccurately prioritize defects and are unable to certify repairs.”

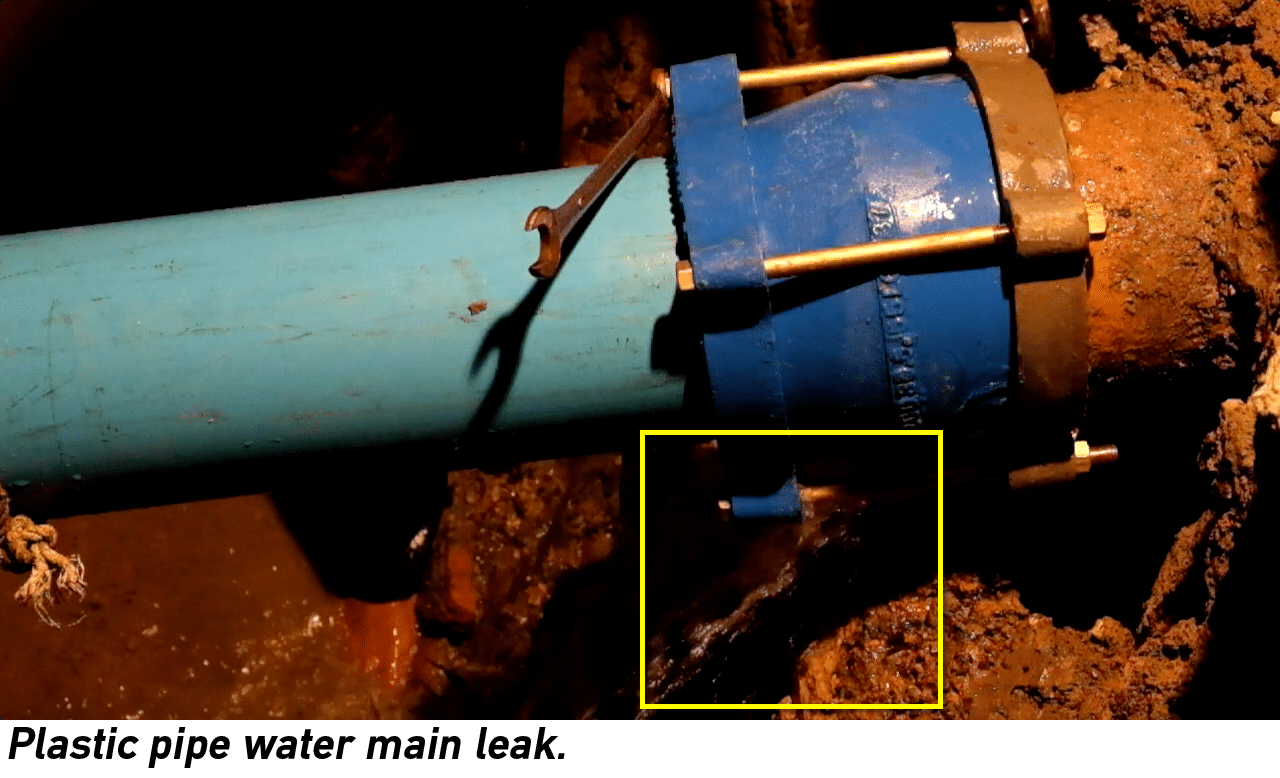

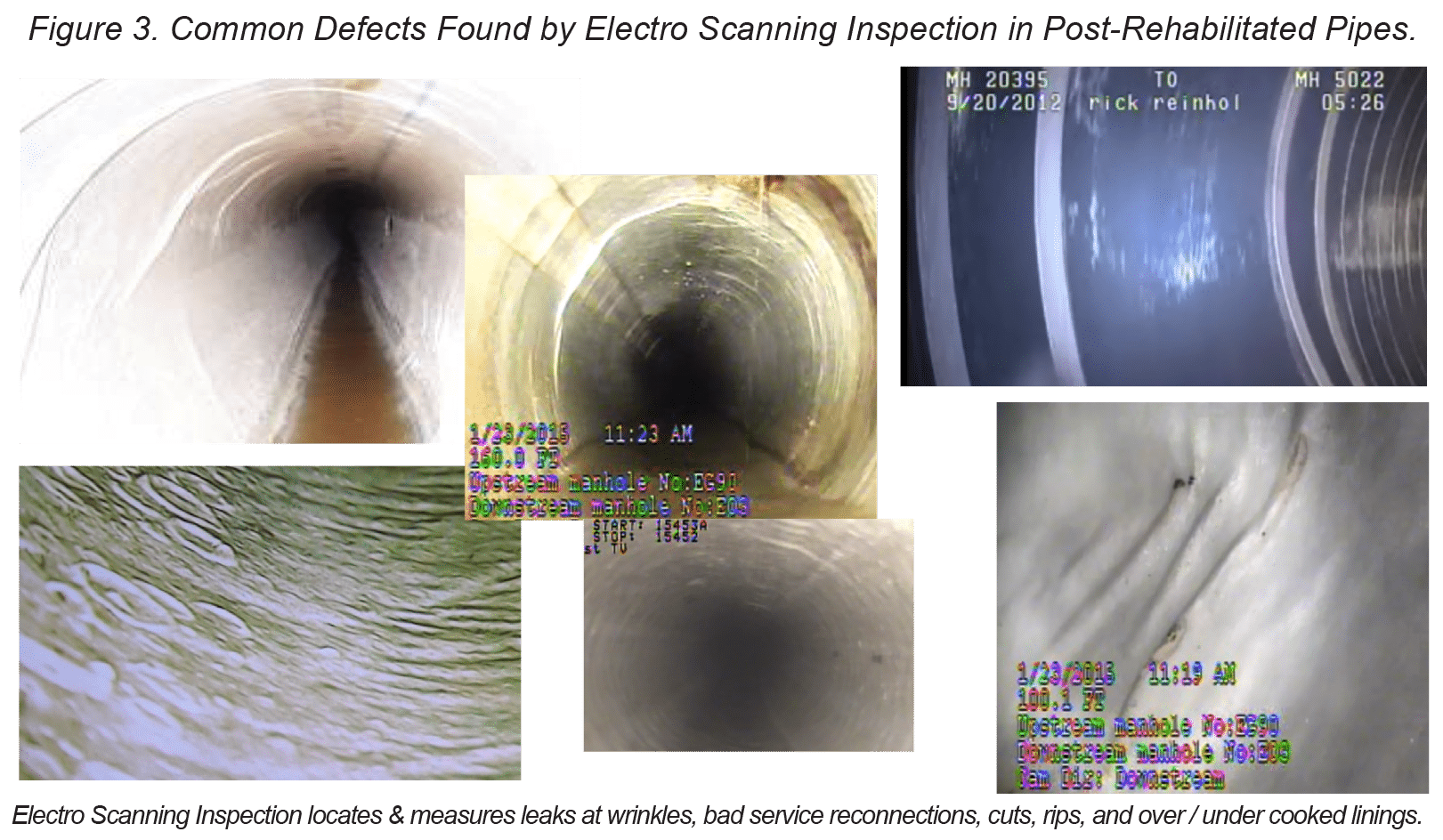

One recent survey compared sewer mains that were previously inspected using high-resolution cameras; however, closed-circuit television (CCTV) recorded less than 1 of every 10 defects found using Electro Scan Inspection.

In another, the majority of CCTV inspections rated pipes as ‘leak free’ or having no evidence of infiltration, with Electro Scan Inspection finding major leaks in over eighty percent (80%) of the pipes surveyed.

In previous surveys, visual inspections simply recorded factory tap locations that connect homes to the sewer main, without recording any defects. In contrast, Electro Scan Inspection automatically located and quantified leaks at each defective service connection.

Authored by the late Ken Kerri, Ph.D., PE, the Electro Scanning Inspection chapter was included in the new Seventh Edition, Volume One, Operation and Maintenance of Wastewater Collection Systems manual to overcome the limitations of visual inspection. The new manual now recommends the use of Electro Scanning Inspection, over CCTV, to evaluate sewer and stormwater pipes, both before and after rehabilitation.

“Sewer managers have long acknowledged the drawbacks of using visual inspection to rate the condition of sewers,” commented Hansen. “But, what surprises most people are the high number of defects found by Electro Scan in relining and point repair projects that were missed by CCTV inspection.”

Common defects in CIPP liners, not typically seen by visual inspection, include accidental cuts, accelerator burns, bad service reconnections, equipment damage, defective epoxy, over-cooking, and lining wrinkles that should be repaired or replaced before project acceptance.

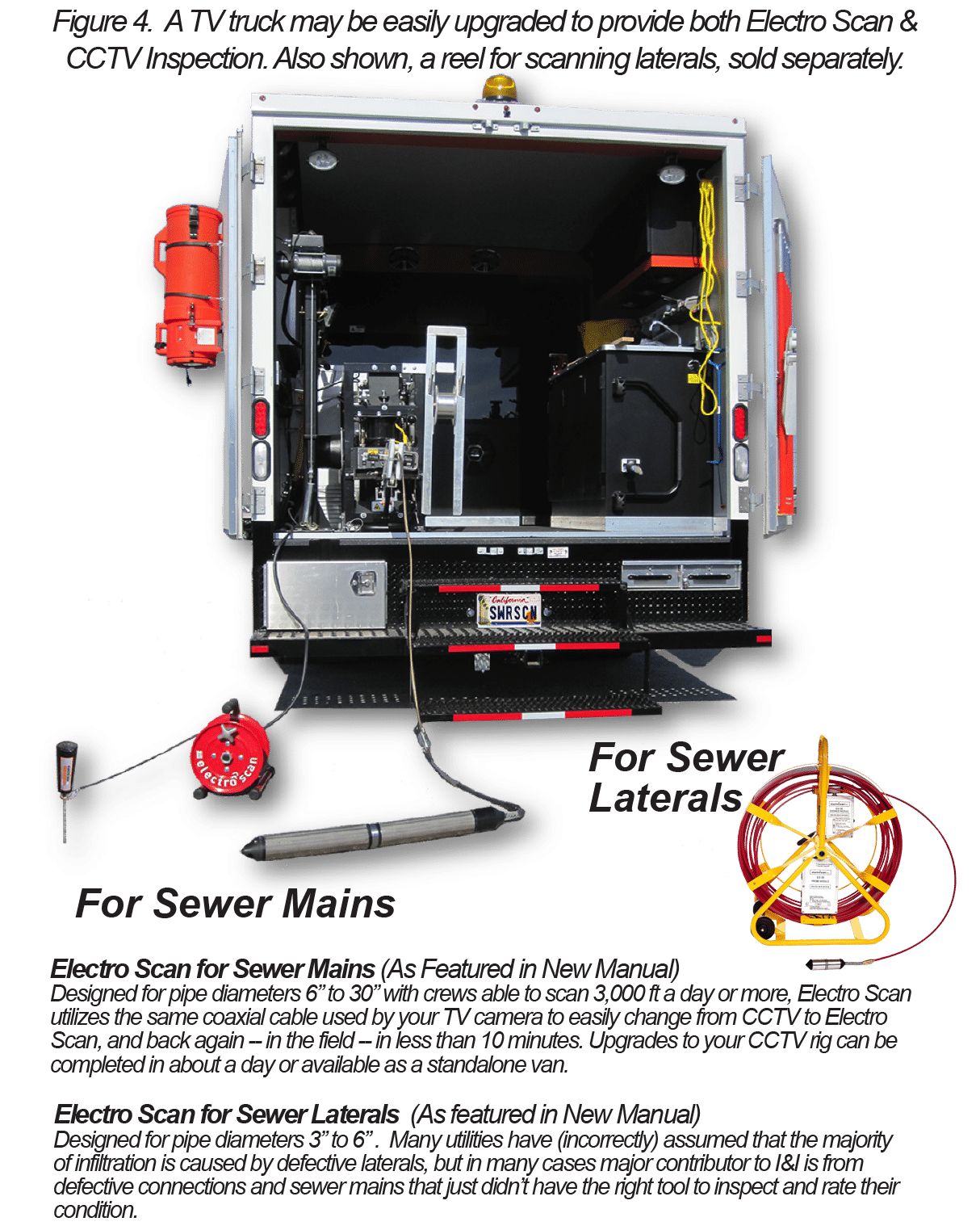

Electro Scanning Inspection can be a contracted service or municipal sewer agencies can purchase equipment that can easily be added to an existing CCTV truck, able to switch from CCTV to Electro Scan, and back, in minutes.

Another recent project performed for a community on the Sacramento River Delta, assessed nearly 13,000 ft of pipe consisting of seventy-seven (77) sewer mains. Fieldwork was completed in 4 days.

In a single day, Electro Scan crews completed the evaluation of 3,978 feet or 28 sewer mains – a company milestone – including several difficult access points where several manholes were 40-ft deep and others located in the middle of a dry creek bed.

In December 2015, the first Electro Scan Leak Detection Van was delivered to San Francisco Public Utilities Commission (SFPUC), with 10 trainees achieving Electro Scan Certification in January 2016.

Today, SFPUC has a full-time team dedicated to running their Electro Scan Leak Detection Van to pinpoint pipe defects where seawater enters its combined sewer system.

Electro Scan Inspection uses patented technology to measure the variation of electrical current that flows through cracks, bad joints, defective service connections, and other defects in non-conductive pipes and estimates the amount of leakage in sewer, water, and gas pipelines.

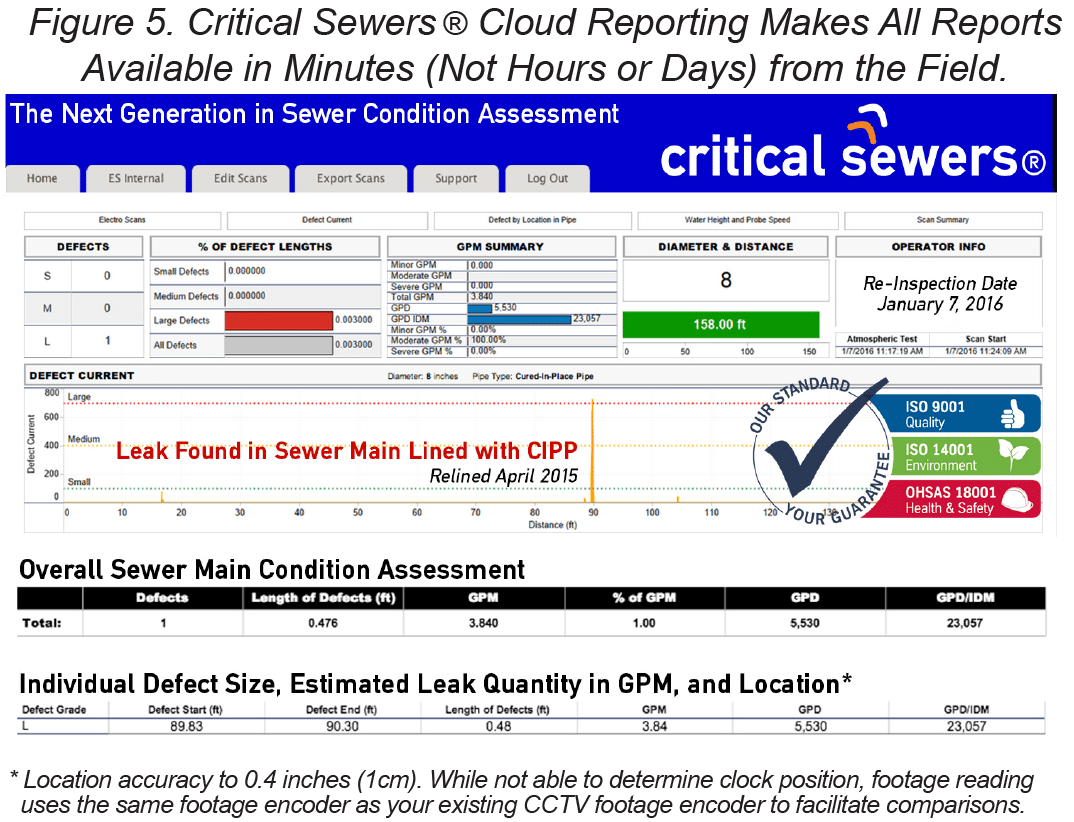

Using its Critical Sewers® cloud application, defects are automatically located and measured in gallons per minute, with unambiguous reports available in minutes.

All Northern California Electro Scanning Inspection projects are being conducted by certified company field crews, in accordance with recommended guidelines published in the Seventh Edition, Volume One, of the Operation and Maintenance of Wastewater Collection Systems manual and in accordance with ASTM F2550-13.

About Electro Scan Inc.

Electro Scan Inc., headquartered in Sacramento, develops proprietary pipe condition assessment instrumentation and cloud applications that automatically locates, measures, and reports defects in sewer, water, and natural gas pipelines, typically not found by legacy inspection methods.

Contact

Electro Scan Inc., Carissa Boudwin, +1 916-779-0660, info@electroscan.com

First published in 1976 with nearly 90,000 copies in print, the OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS manual is used by operators, managers, and consulting engineers, worldwide.

First published in 1976 with nearly 90,000 copies in print, the OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS manual is used by operators, managers, and consulting engineers, worldwide.

Electro Scan’s technology is not only explained in Section 4.4 of the Seventh Edition, but also depicted in numerous illustrations, statistical analyses, and practical applications, in accordance with

Electro Scan’s technology is not only explained in Section 4.4 of the Seventh Edition, but also depicted in numerous illustrations, statistical analyses, and practical applications, in accordance with  Important updates contained in the Seventh Edition suggest altering the acceptance criteria for rehabilitated pipes using Electro Scanning Inspection to assess the effectiveness of cured-in-place pipe (CIPP), service re-connections, and point repairs, explaining the importance of quantifying pre- and post-rehabilitation inspection results.

Important updates contained in the Seventh Edition suggest altering the acceptance criteria for rehabilitated pipes using Electro Scanning Inspection to assess the effectiveness of cured-in-place pipe (CIPP), service re-connections, and point repairs, explaining the importance of quantifying pre- and post-rehabilitation inspection results.