Persistent levels of I&I drive a progressive utility to install Electro Scan’s innovative FELL inspection tool to pinpoint sources of infiltration.

SACRAMENTO, CALIFORNIA, US, February 18, 2021 /EINPresswire.com/ — Electro Scan Inc. announced today that a large U.S. Southeastern utility has purchased and installed the company’s innovative and industry-leading Focused Electrode Leak Location (FELL) technology into one of its existing closed-circuit television (CCTV) pipe inspection trucks. This “plug-and-play” FELL installation immediately transformed their infiltration inspection program with the ability to pinpoint exact locations of infiltration, not previously possible with CCTV cameras.

“The utility reached out to Electro Scan in July 2020, during the height of the COVID-19 pandemic, and requested a FELL technology demonstration in their own system. Surveying existing pipe materials and recently installed Cured-In-Place Pipe (CIPP) liners, the resulting data convinced utility managers they had finally found an inspection approach that made sense,” stated Mike App, Vice President, Electro Scan Inc.

“The field demonstration offered a clear view of how powerful FELL data is for helping set rehabilitation priorities,” continued App.

Facing significant unwanted infiltration in its gravity sewer collection network, and the serious consequences from overloading available wastewater treatment capacity, the utility had been frustrated for decades in using conventional inspection technologies, such as CCTV, Smoke Testing, and Dye Flood Testing, without meaningful results or success in reducing infiltration.

“Utilities everywhere are finding that our innovative condition assessment technology can help save millions of dollars in cost avoidance.“

— Chuck Hansen, Chairman & Founder, Electro Scan Inc.

Costly sewer lining programs that relied on CCTV to certify water tightness were shown to be equally ineffective.

Electro Scan installed its FELL inspection equipment into the utility’s existing CCTV inspection trucks in late 2020, taking only 6 hours. Company staff then provided training and initial oversight to utility crew members, and within 1 day the utility was performing inspections with in-house personnel.

Utility crews could easily change from CCTV to FELL, and back again, in less than five minutes, without the need for any specialized tools or complicated procedures.

Overnight, the new FELL capabilities completely changed how rehabilitation decisions were made.

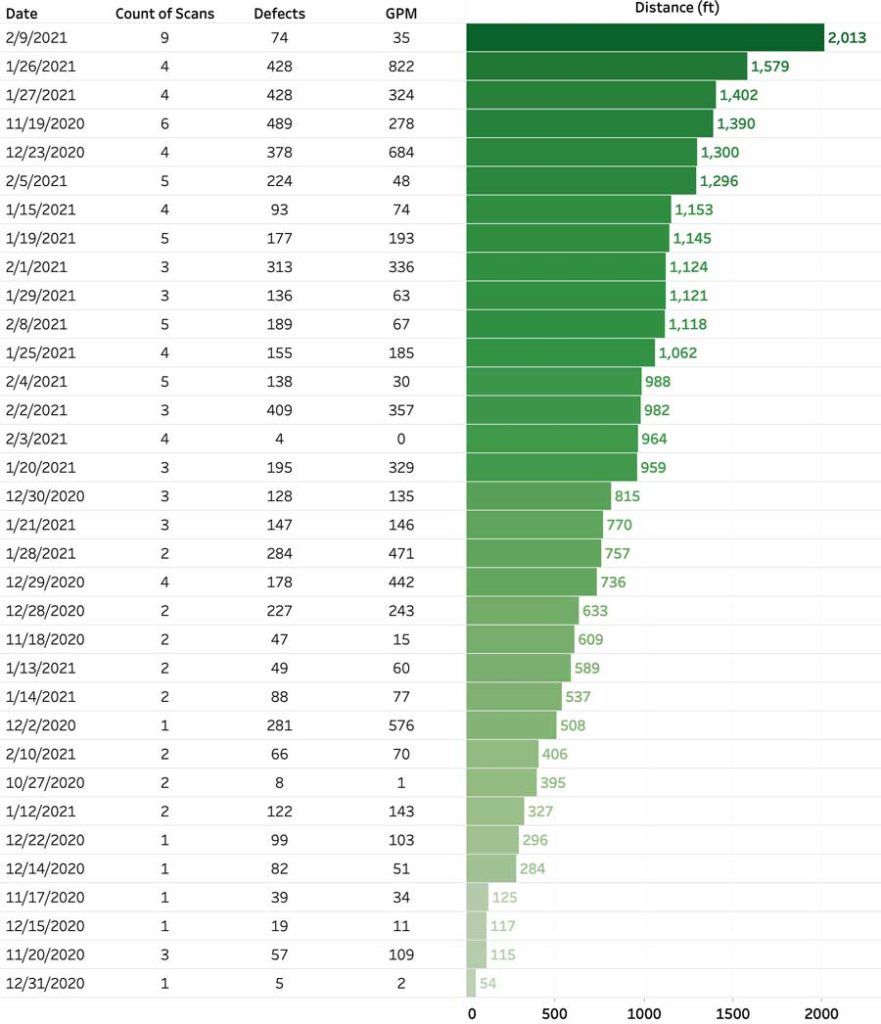

“From the first day, everybody jumped right in to help make this inspection approach a success, and now the team is averaging more than 2,100 feet of FELL pipe inspection per day. In fact, they have already completed six (6) miles of inspection work in 2021 alone,” shared Mackenzie App, Eastern Field Sales Manager and Operations Specialist.

“Working with this team was exciting because they know this technology is making a big difference,” App continued.

With a significant amount of unlined Vitrified Clay Pipe (VCP) remaining in their system, the field demonstration remarkably showed that while there are some pipes contributing to excessive infiltration rates, many were not. In fact, results indicated that the so-called “80/20” rule was in full effect – where 80% of the infiltration problems originated from just 20% of the pipes; even from VCP lines that were 50-years-old or more.

“We see this time and again at almost every utility, across the nation” offered Mike Condran, PE, Vice President and Southeast Regional Director, Electro Scan, Inc.

“Unambiguous and unbiased FELL data documents precisely where the worst pipe defects are located, and amazingly only a handful of those contribute the majority of infiltration,” Condran stated. “FELL data gives “X marks the spot” clarity to owners, delivering convincing information to make proper risk-based decisions and reduce capital spending,” continued Condran.

Interested parties are invited to watch this informative video on how FELL inspection locates leaks at joints in VCP or newly rehabilitated pipes.

Another significant issue for the utility was the ability to inspect large diameter interceptors, which normally had to be bypassed to complete traditional CCTV inspection. Since FELL assessment never requires cleaning or bypass pumping, the utility is now able to quickly assess conditions in their interceptors that had never before been inspected.

An essential part of the decision to invest in FELL technology was the fact that previous legacy pipe inspection programs gave inconsistent and often contradictory results. Frustrated with the status quo for trying to control infiltration, utility managers knew they needed to find a more reliable and scientific approach.

After the field demonstration, utility decision-makers reached out to their counterparts from other utilities across the country, that had adopted FELL inspection, to verify successes with this innovative technique. With Electro Scan’s unique technology gaining broad acceptance to support both smart rehabilitation priority setting and to document post-rehabilitation water tightness, the decision to purchase the equipment was easy to make.

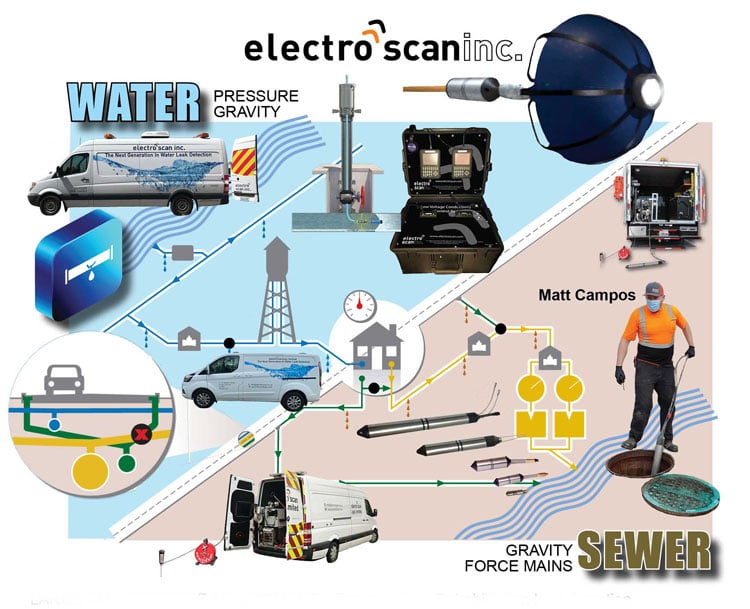

In addition to the utility’s new capability to inspect its gravity collection lines, Electro Scan recently announced its revolutionary ‘DELTA’ and ‘TRIDENT’ multi-sensor tethered probes, available to assess force main condition.

Several Electro Scan force main inspection projects are already scheduled this year from California to Florida.

“Over the past 10 years, Electro Scan has completed nearly 200 gravity pipe inspection projects totaling more than 4 million linear feet,” stated Chuck Hansen, Founder & Chairman, Electro Scan Inc.

“And now, pipeline owners have the ability to assess pressurized pipes using FELL technology, including potable water networks and sewer force main to precisely locate defects that can prevent catastrophic failures,” indicated Hansen.

This latest success story in the U.S. Southeast is just one more example of how FELL technology is supporting utilities everywhere to “Build Back Better” and “Find the Leak Before the Break.”

Given the long road to economic recovery during the post-COVID pandemic, today’s capital budgets are being pushed to their limits. As a result, utility managers are relying on innovative technologies and strategies to deliver immediate financial benefits and capital savings where outcomes have the greatest overall benefit.

ABOUT ELECTRO SCAN INC.

Headquartered in Sacramento, Calif. and founded in 2011, the Company designs, develops, and markets proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing, analytics, and reporting applications that automatically locates, measures, and report defects typically not found using legacy inspection methods. In 2021, the company was named “Most Innovative Leak Detection of the Year” for 2021. Electro Scan field crews and its authorized partners have been designated ‘essential workers’ adopting Coronavirus Health & Safety Standards, including appropriate use of Personal Protective Equipment (PPE) and Social Distancing standards, in accordance with state mandates and CDC recommendations.

#ai #aicctv #asce #astmf2550 #cctv #cipp #conditionassessment #f2550 #faultycipp #fell #forcemain #IoT #infiltration #infrastructure #innovation #infiltration #inspection #leak #leakage #leakdetection #machinelearning #nassco #pacp #pipeline #piperepair #project #sewerai #SaaS #trenchless #innovation #rehabilitation #trenchlesstechnology #trenchless #sewer #wastewater #utilities

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn