After spending decades and millions of dollars rehabilitating sewer pipes across its service area, a large coastal utility embarked on a pilot pipe condition assessment program for 25,000 linear feet in areas prone to high unwanted infiltration rates.

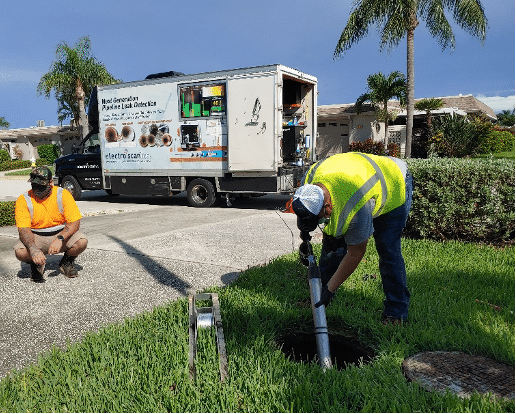

Electro Scan’s Focused Electrode Leak Location technology, or FELL, offers an innovative departure from legacy pipe inspection methods, such as visual CCTV, dye testing, smoke testing, among many others. The key advantages of FELL inspection is obtaining precise pipe defect locations, to within 1 cm, as well as a quantified infiltration flow rate for each defect, reported in Gallons Per Minute.

STARTLING RESULTS

The utility was interested to compare performance between unlined, 50-year-old vitrified clay pipe, or VCP, and pipes that were rehabilitated using Cured-In-Place Pipe, or CIPP. There were two CIPP classes tested, those installed in the last two years, and liners installed 10-15 years ago.

Care was taken to split the total project inspection lengths among the VCP and two CIPP classes into equal thirds, making direct performance comparisons easier. Perhaps remarkably, the 50-year-old VCP contributed a mere 20% of potential infiltration, compared to 50% of infiltration sources present in the newer CIPP class. Moreover, on a relative basis, the study showed that rehabilitating roughly one half of equivalent length of VCP will result in comparable I/I reductions from similar CIPP rehabilitation.

COMPARING FELL AND CCTV

Side-by-side comparisons were performed between FELL and CCTV inspection methods. Strikingly, the NASSCO-certified inspection reports identified only 34 individual pipe defects contributing to infiltration.

By stark contrast, FELL results identified 1,188 individual infiltration defects. As an added benefit, FELL results pinpoint whether leaks are occuring in the pipe wall or at the customer tap connection. In this case, of the 467 tap connections encountered, CCTV identified 3% to be defective, as opposed to 74% defective taps documented by FELL machine-intelligent technology.

CONSISTENT FINDINGS WITH OTHER UTILITIES

Unfortunately, these results from the August 2020 study are consistent with findings from other wastewater utilities around the US and internationally. In fact, two other large Florida studies from 2019 and the Spring of 2020 reveal essentially the same conclusions. And, a similarly sized midwestern project completed in late 2019 also supports these results.

With all the new fiscal challenges to utility owners posed by the COVID-19 pandemic, there is an essential need to make the most of available capital resources. This study has definitively shown that the most recently lined sewer pipes using CIPP rehabilitation are actually contributing to more infiltration than the original pipes installed in the early 1970s. Utilities can no longer accept ‘business as usual’ inspection methods to approve of work that does not meet intended results to reduce unwanted infiltration, driving up costs to rate payers.

Details of this study may be requested by contacting Electro Scan Inc.