It’s a simple fact — pipe defects that leak water, also leak electricity.

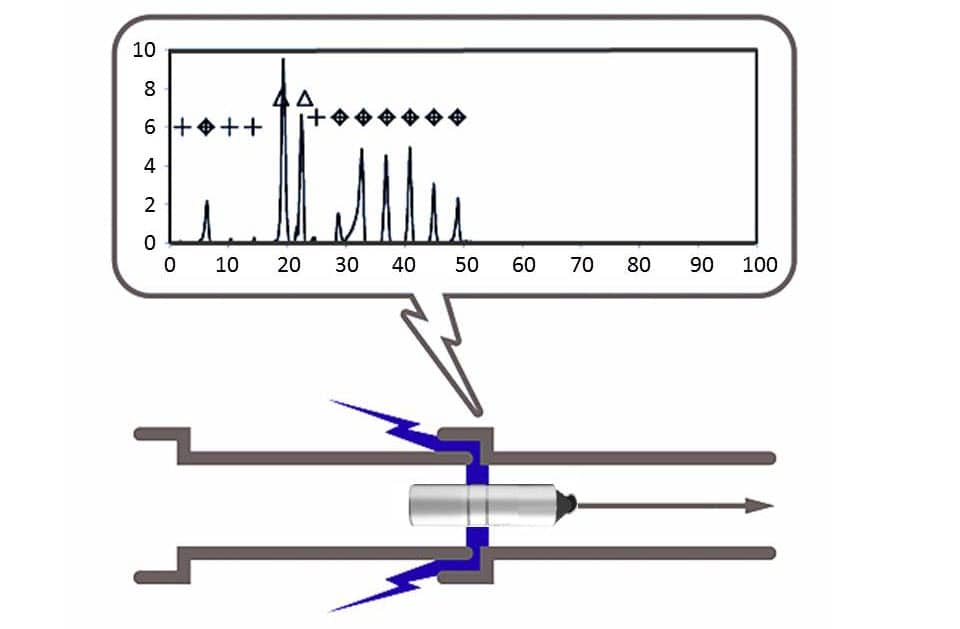

Since electricity flows through the slightest crack and around corners, Electro Scan finds ALL defective pipe joints and sewer tap connections that CCTV can’t by visual observation. In addition to identifying leak locations, Electro Scan indicates the size, too. The bigger the electrical flow, the bigger the defect, the bigger the leak potential. The type of defect – joint, tap, or crack, is shown by the pattern of the electric current.

Leaks in sewer pipes are located by measuring the electricity flowing from a probe. As the probe is pulled through a pipe, electricity is used to scan the pipe indicating all defects – hence the term ‘Electro Scan.’

Electro Scan Inc.’s proprietary technology and intelligent data management solutions marks the location of joints, shown with a plus mark “+” and when coinciding with a diamond mark “◊” indicates a defective joint.

Peaks between joints are indicated by a triangle mark “Δ” show a structural defect or defective service connection.

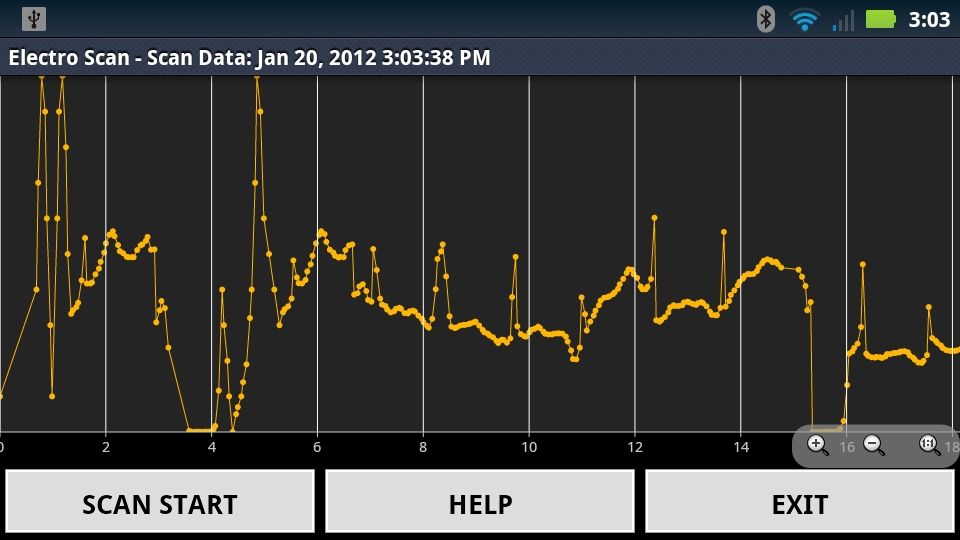

Results are transmitted, processed, recorded and displayed on Electro Scan Inc.’s smartphone app. The scan data is exported to Electro Scan Inc.’s Critical Sewers™ cloud computing app for post-processing and re-transmission to the smartphone.

Once resident in the Electro Scan Inc. Critical Sewers™ cloud computing app, Member Only users can complete additional analysis and reporting, including integration with Geographic Information Systems and use with Hydraulic Modeling. An Executive Dashboard allows rapid access to scans completed that day or week.

Electro Scan test results automatically transmitted via Bluetooth with results processed remotely on Critical Sewers™ cloud computing app and displayed on Smartphone.

Of course, electro scan only works if a pipe does not conduct electricity. Fortunately, most sewer pipes are poor conductors of electricity, including, clay, plastic, concrete, reinforced concrete, and brick etc. Since Electro Scan relies on water in the pipe to provide electrical contact with the pipe wall, it will detect all defects of a pipe submerged in water. To Electro Scan the entire circumference of a pipe, the pipe need only be full at the probe location, eliminating the need to have the entire sewer main full of water. While filling a sewer lateral for testing is straight forward, Electro Scan Inc. has developed specialized equipment and techniques (i.e. ES-Air Push Rod for Sewer Laterals and ES-Funnel Plug for Sewer Mains) to do this easily and quickly.

Electro Scan Technology Delivers Repeatable Test Results, With Only Slight Variation; CCTV Does Not

Ever have two CCTV operators review the same sewer line and compare their results? Even after extensive training, pictorial guides, and years of field experience, results may vary – substantially. Not so with Electro Scan Inc.’s breakthrough new products.

As shown below, tests taken months apart, show the same information. Electro Scan provides consistent and repeatable test results with no significant variations.

New Technology Finds ALL Pipe Defects That Can Leak

Electro Scan finds all pipe defects that can leak. It shows the defect location within inches, the size and the type. It does this independently of the operator. Electro scan is quantitative supplying comprehensive metrics that fully describe the leak potential of a pipe. Electro Scan metrics have a fractal nature, so they can be used to compare the leak potential of sub-basins, pipe reaches, manhole-to-manhole pipe segments, or individual joints, readily integrated into a utility’s GIS.

The present generation of sewer evaluation studies began with CCTV over 30 years ago. For the first time, managers & engineers could view the inside of a sewer pipe and reveal major structural damage, grease, sedimentation, blockages, misaligned and broken joints, roots, and pipes actually leaking at the time of the inspection. Over the years, camera resolution and picture quality have dramatically improved, aided by increased lighting control and ability for operators to pan, tilt, and zoom; however, the subjective nature of visual observations and inability to “see” into joints and service connections, has caused wastewater professionals to search for alternatives.

Electro Scan represents the next generation in sewer leak detection. Initially tested by consulting engineers and public works managers as a last resort to help determine why recent pipe rehabilitation projects had failed. Electro Scan was found to locate problems that CCTV could not find. Comparison studies have found that CCTV generally misses 2 out of 3 defects that cause leaks, and often missed the largest. Consequently, field work must be re-done to re-rank and re-prioritize recommended rehabilitation.

Electro Scan ushers in a new era in sewer assessment using the next generation of sewer leak detection technology. For the first time in the history of sewer evaluation, Electro Scan Inc. products provide all the information required to carry out cost effective infiltration/exfiltration mitigation programs, including quality assurance and quality control testing of all rehabilitation work.

Electro Scan Technology Has No Peer

No Electro Scan-comparable sewer condition evaluation technology exists. As a result, change is inevitable for CCTV manufacturers, contractors, software providers, and many others that have relied on this aging technology. CCTV cannot accurately evaluate joints or taps – the main source of infiltration; and other methods, such as smoke testing, dye flood testing, sonar and laser inspection, only give vague indications of where, how much, and why a pipe leaks — but Electro Scan can.

Matching our next generation assessment tools, Electro Scan Inc. also utilizes the latest standards of intelligent data recording, display, transmission, storage and computer processing technology. The data is transmitted from the Electro Scan Inc. probe via Bluetooth to a smartphone app. With readings displayed in real time, data is then exported to Electro Scan Inc.’s Critical Sewers™ cloud computing app for processing and up-to-the minute viewing via our Executive Dashboard. Automatically transferred back to the smartphone, reports can be displayed on the smartphone or printed to a ruggedized printer and handed to a homeowner.

Once data is resident in the Electro Scan’s Critical Sewers™ cloud computing application, subscribers can complete additional analysis and reporting, including integration with Geographic Information Systems, Hydraulic Models, in addition to comparison with legacy CCTV, manhole inspection, smoke and dye flood tests.

Systems available for collecting Electro Scan field data include the ES-38™ for Sewer Laterals, for scanning 3 to 8 inch diameter sewer laterals, ES-660™ for Sewer Mains, for scanning 6 to 60 inch diameter sewer main lines, Smartphone App, for collecting data in the field and printing reports, and Critical Sewers™ cloud computing app, used to remotely process data collected in the field and store customer data in a secure hosted environment.

Summary

Electro Scan finds all pipe defects that leak. It shows the defect location within inches, its size, and type (i.e. joint, service connection, structural defect, etc.). It does this independent of an operator, without relying on visual observations, providing accurate, consistent, and sustainable results. As the industry’s only quantitative measurement of a sewer’s leak potential, Electro Scan Inc. is uniquely positioned to overhaul the present method for prioritizing sewer rehabilitation for actionable and supported decision making.